ARC Welding

Understand the basics of electric arc welding with electrodes. Learn to handle equipment, read weld symbols, and ensure strong, reliable joints.

Course Details

Overview

Arc welding is a versatile group of welding processes in which heat is generated by an electric arc to join metals. This process generally does not require external pressure and may or may not use filler material, depending on the thickness of the base metal. One of the most widely used methods under this category is Shielded Metal Arc Welding (SMAW), where coalescence is achieved by heating the workpiece with an electric arc formed between a flux-coated electrode and the metal surface.As the electrode melts, it provides the filler metal necessary for the weld. Meanwhile, the flux coating decomposes from the arc heat, producing gases that shield the molten weld pool from atmospheric contamination. It also forms a protective slag layer over the weld bead, enhancing arc stability and improving weld quality.Arc welding is known for its simplicity and portability. The equipment is relatively inexpensive and easy to operate, making it suitable for a wide range of applications. A broad selection of electrodes is available, allowing this process to be used for joining various metals and their alloys in different positions while still achieving high-quality welds.

Career Prospects

Urban Industrial Technical Institute provides an intensive 2-month Arc Welding training program tailored for individuals who want to master manual metal arc welding techniques. Trainees gain hands-on experience with standard tools and welding positions, guided by experienced instructors. Upon successful course completion, students receive a certification and are offered placement assistance in various fabrication and construction companies. As one of the top arc welding training centers in Jamshedpur, Jharkhand, Urban Industrial Technical Institute ensures students are job-ready and well-equipped to work in industries like shipbuilding, pipework, repair maintenance, and infrastructure projects.

Program Structure

Curriculum

Certification

Basic Arc Welding certification suitable for entry-level positions.

Enquire About This Course

Frequently Asked Questions

What are the eligibility requirements for this course?

Generally, candidates should have completed 10th standard (Class X) or equivalent. Specific requirements may vary by course. Age requirements typically range from 16-40 years. Medical fitness may be required for certain technical trades.

What certification will I receive?

Basic Arc Welding certification suitable for entry-level positions. This certification is recognized by industry standards and helps in job placement both in India and abroad.

Do you provide placement assistance?

Yes, Urban ITI provides comprehensive placement assistance including resume preparation, interview training, and direct connections with employers in India and Gulf countries. Our placement team works closely with leading companies in the industry.

What is the course fee structure?

Course fees vary by program duration and specialization. We offer flexible payment options including installment plans. Contact our admissions team at +91-8235585588 for detailed fee information and available scholarships.

Are there any additional costs?

Additional charges may apply for materials, equipment usage, and certification fees. International certification fees are separate where applicable. All costs are transparently communicated during the admission process.

Recommended Courses

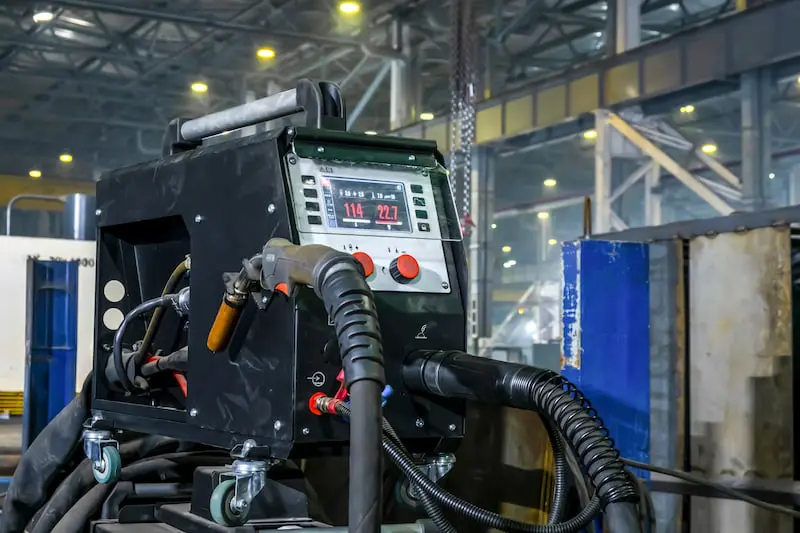

MIG CO2 Welding (Carbon dioxide)

MIG CO2 Welding (Carbon dioxide)MIG CO2 Welding (Carbon dioxide)

Learn the essentials of CO₂-based Metal Inert Gas welding, focusing on safety, equipment handling, and high-quality weld joints in various applications.

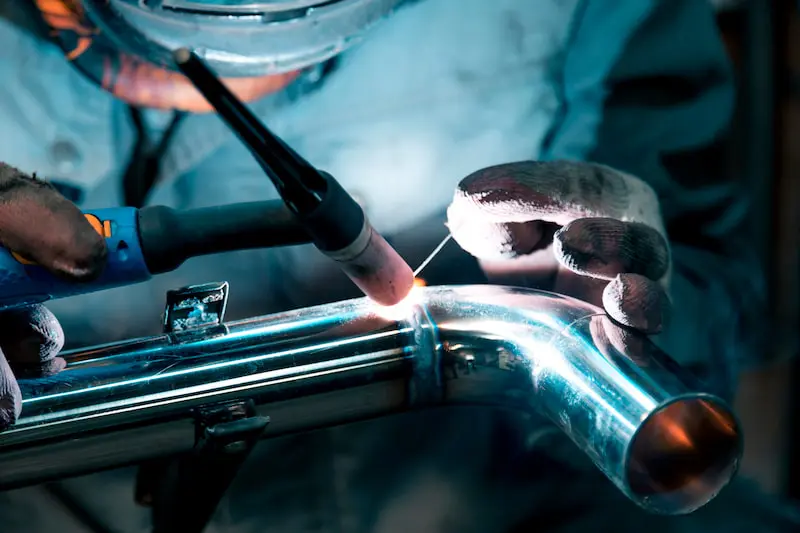

TIG (Tungsten Inert Gas) Welding

TIG (Tungsten Inert Gas) WeldingTIG (Tungsten Inert Gas) Welding

Master precise welding techniques using tungsten electrodes. This course emphasizes clean, high-strength welds ideal for critical applications like aerospace and piping.

MIG Welding (Metal Inert Gas Welding)

MIG Welding (Metal Inert Gas Welding)MIG Welding (Metal Inert Gas Welding)

Gain hands-on training in MIG welding using inert gases, suitable for beginners aiming to work in automotive, construction, or manufacturing industries.